Whether your water tank or boiler has been recently repaired, installed or has started giving you trouble, it’s important to make sure that it is in safe working order. A hydrostatic pressure test will do just that.

In this article we’re looking at hydrostatic pressure testing, including what it is, what it involves and just why it should be performed.

What is a hydrostatic pressure test?

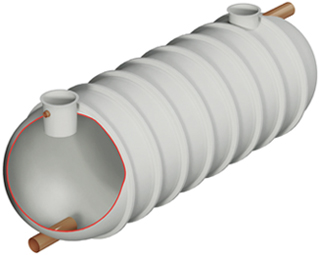

Simply put, hydrostatic pressure testing is a rigorous leak test performed on various ‘pressure vessels’- your hot water storage tank or boiler, for instance. It can also be performed on piping.

It doesn’t just test for existing leaks, however. A hydrostatic pressure test will also examine the structural integrity and current performance of the tank.

What does a hydrostatic pressure test involve?

A typical test will involve filling your tank or vessel with pressurised liquid, usually water. The tank will be filled until the water reaches a certain pressure. This pressure is often higher than the pressure your boiler or tank might normally experience – sometimes 150% more.

Dyes may be added to the water in order to make the results of the test clearer as it is being performed. This makes leaks easy to identify.

The pressure level is held for a certain amount of time to allow for a meticulous inspection to take place. The inspection will be able to identify any existing leaks and will also be an effective test of durability and performance.

When do I need a hydrostatic pressure test?

The test is best performed when servicing your tank, to decide whether or not it is able to provide reliable performance in the future. Hydrostatic pressure testing is also a helpful post-repair process, giving your tank a final test to ensure it has been brought back up to working order.

If leaks have not been fully repaired, or return under certain pressure demands, the pressure test will be able to identify this. The results of the test will influence whether or not your tank needs further repairs or total replacement.

How often should I have a hydrostatic pressure test?

This test should form a part of your regular maintenance schedule for your boiler or storage tank. This schedule will change depending on the age and type of pressure vessel, so discuss this with a reputable company to make sure you’re receiving the most suitable service for your needs. A pressure test every one or two years should suffice, but will also be required after any major repair work has been carried out.

Who can carry out a hydrostatic pressure test?

When testing for leaks in any kind of pressurised environment, you should enlist the services of a professional, qualified inspector. You can talk to your inspector about the current state of the vessel, as well as any repairs that have been or need to be carried out.

A competent inspector will tailor their service to your tank, and will work with the highest standards of safety in mind at all times. Once a test is completed, they will be on hand to offer professional insight for future maintenance, further repairs or necessary replacements that may need to be made.

Wildon UK are proud to provide a hydrostatic pressure testing service to customers throughout Stoke-on-Trent, Staffordshire and across the entire UK. Our experienced team work diligently to make sure every test is carried out using the most suitable procedure for you, and are happy to help with any questions you might have. To find out more about all of our services, get in touch with us today.

Go back to