Farms can be a dangerous place to work. Despite farmers making up less than 2% of the workforce, the industry accounts for 19% of work-related fatalities every year. Due to the physical demands of the job, some injuries are perhaps to be expected. However, the handling of hazardous substances is a dangerous part of the job that is often overlooked. From pesticides to additives and machinery fluids to toxic slurry gas, there are many substances that farmers have to know how to handle safely on a frequent basis. This month, we’ll be focusing on how to safely work with slurry.

Dangers of slurry

The toxic gases that are associated with slurry are created as the agricultural waste materials decompose. Methane, carbon dioxide, ammonia and hydrogen sulphide – the most dangerous of all – are all produced in slurry and will be present at the surface of the slurry tank/pit and throughout the mixture. Slurry gases are heavier than normal air and will settle at the top of the slurry but it can be hard to establish how large an area they cover and how far is a safe distance, particularly once the slurry starts to be mixed.

The most hazardous of the gases is hydrogen sulphide which has the particularly devious side effect of knocking out your sense of smell, meaning you won’t notice that you’re inhaling this lethal substance. The noxious cocktail of slurry gases can quickly become lethal, causing irritation of they eyes and respiratory tract, dizziness, nausea, disorientation, collapsing and finally, if you remain exposed, fatalities as breathing stops.

How to avoid accidents

It is vital that laborers that work with slurry are familiar with the risks and that prudent health and safety is carried out at all times to avoid incidents. For example, when working with and approaching a slurry tank, appropriate protective clothing should be worn. A simple protective face mask is not sufficient; full breathing apparatus is necessary.

Make sure you thoroughly prepare for slurry work before carrying it out to ensure you will be working safely. Some safe working practices include:

- Keep unnecessary openings to slurry tanks covered at all times

- Remove animals and children from the room and/or vicinity

- Open doors and windows to maximise ventilation

- Where possible, mix on windy days to increase fresh air and ventilation

- Use breathing apparatus

- Start the pump/mixer and then leave the building for as long as possible – 30 minutes should be a minimum

- When carrying out slurry work in the building, ensure the worker has a harness attached to, ideally, two others who stay outside the building

- Gas meters can help determine air toxicity post-mixing but do not rely on them beforehand or use them in place of breathing apparatus

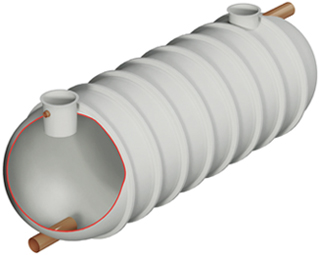

Wildon UK can provide customers across Stoke-On-Trent and the rest of the UK with reliable, high quality slurry systems. Our skilled and experienced team can install a variety of efficient systems which use advanced technology to turn your farm waste and organic matter into eco-friendly fertiliser. Get in touch with our professional team today with any enquiries.