With so many different types of pumps now available, unless you’re an expert in the field it can be rather confusing knowing which one is the best to use in order to get the job done quickly and efficiently, meeting all your requirements during the process. That’s why our team of experts have drawn up a user-friendly guide to pumps that highlight the sewage pumps that are the most commonly used here at Wildon UK in order to offer the most reliable and competent sewage treatment for domestic and commercial customers alike. Let’s have a look at this guide to sewage pumps.

Clean water pumps

Essentially the clean water pump manages all size scales of water extraction, efficiently moving water from one area to another. For instance, if you’ve been affected by the recent flooding in the UK, then a clean water pump can quickly move large quantities of water out of your home and back to where it came from, allowing you to get back to normal as quickly as possible.

Slurry Pumps

Generally used to remove slurry (thin, sloppy mud or cement) via a vertical, suction pump. Due to the abrasive nature of slurry, the pumps are lined with rubber and can have their plates replaced in order to maintain a sufficient service. The slurry pump is also frequently used for mining, mineral processing, agriculture and power plant.

Borehole pumps

The borehole pump ultimately allows us to access water that is contained underground. A narrow well runs deep underground and when using an electric pump and modern technology, we can extract the water from beneath. Water can also be extracted, providing a constant water supply that can be used for outdoor use, or with further filtration methods can be consumed as drinking water and utilised for indoor uses.

The water can be used for domestic or commercial use, although largely used for satisfy domestic needs supplying water to homeowners throughout the UK, and primarily supplements the water that we would otherwise rely on reservoirs for.

Water booster pumps

Water booster pumps are used to increase the amount of gas pressure that is supplied, either on a small scale, such as for one shower, or a larger scale perhaps for industrial purposes. Either way, the water booster pump can enhance the current gas pressure of an entire premises using either an end to end suction, horizontal split case or in-line circulator to do the job as efficiently as possible, ensuring quick and noticeable results.

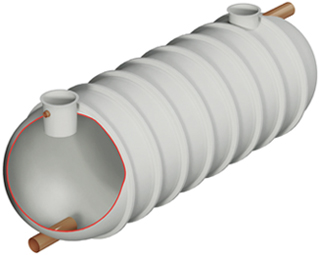

Sewage pumps

Sewage pumping is usually carried out using submersible pumps. Again, these can either be large or small submersible pumps depending on the size of the job e.g. domestic or industrial scale. As well as the small and large pumps, there is also the Chopper pump that is most commonly utilised for industrial use of larger concentrations of tougher solids that the ordinary sewage pump would struggle to handle.

The sewage pump became particularly popular in the 60s when the guide-rail system was created that allows the submersible pump to be lifted out of the pump station when it was damaged so repairs could be carried out. This provided an alternative to sending someone down into the sewage pit that posed high risks.

So, before you go ahead and use any pump, why not use this handy guide to sewage pumps, all of which can be supplied or hired by our team here at Wildon UK and can guarantee that you see fast and noticeable results.

If you have any queries or would like to speak to one of our sewage specialists, please do not hesitate to give us call today and we’ll be more than happy to help.

Go back to