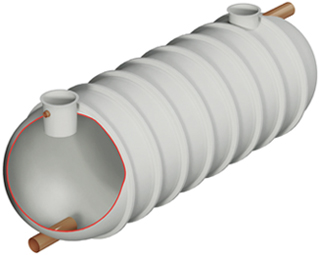

Wildon UK Limited were contacted by a private operator of a large industrial sewage treatment works. The site was originally constructed during 1942 for the treatment of effluent from a manufacturing facility that was producing aero parts to assist with the war effort. The sewage works had only ever had one up grade and this was during the mid 1970’s. Wildon UK limited were contacted by the operators as the site required a complete overhaul to include all electrical and mechanical equipment. After successfully tendering for the work, Wildon UK limited were appointed principal contractor for the project. Within the first month of the project our engineers quickly ascertained that the works original design was not suited to the proposed new use of the site the sewage treatment works served. The main issue that could affect the future trouble free operation of the treatment process was the fluctuating hydraulic loads now imposed on the inlet compared to the flow rates once received from the original factory site. After discussion with the project consulting engineers a solution was quickly developed and the use of a large balancing tank was proposed. Wildon UK Limited then had a bespoke 60,000 litre GRP balancing tank constructed to our exact drawings, all internal pumping equipment was designed and sourced and control equipment designed and built.

The proposed installation site was within an area that any excavation could have an effect on surrounding equipment and concrete structures. The excavation would have to be a minimum of 5.5 metres deep, 6 metres wide and 8 metres long. The nearest existing structure that could be affected by this large excavation was only 600mm away. It was decided that the only way to safely excavate a hole this large was to construct a piled cofferdam system. All work was conducted in house by Wildon UK limited staff to include the installation of the sheet piles, the installation of the cofferdam and all concrete works associated with the installation. For the duration of the works our own all terrain crane was transported to site to ensure we had full control of the installation.

The installation of the balancing tank was completed on time and within budget with no damage to any surrounding equipment.